Part Inventory

In-Process Inventory

Sometimes referred to as not-stocked parts, in-process inventory relates to parts that are purchased for in-process tickets that will not be stocked. These are parts that you have to purchase on a vehicle-by-vehicle, or ticket-by-ticket, basis. You need to track their status through the system, but once the ticket is completed you don't want to think about the part again. Some examples:

- Engine

- Water Pump

- Brake pads/rotors

The above items you're unlikely to stock, but you still need to purchase them and keep track of them as they move through the system. As such, there are several key benefits to managing your in-process inventory:

- Ensure that a part gets purchased

- Know how that part was paid for

- Ensure that a part was applied to a ticket/sold

- If not, providing a way to track in-process parts that aren't getting sold to ensure the part gets returned.

In-Process Inventory is automatically created when you add a part to a ticket or a part order and it is not selected from part inventory. Any In-Process or Not-Stocked inventory should always get cleared out eventually. If you see a line item in your Part Inventory for a not-stocked part, there's probably an issue you need to address:

- Added to a ticket but not purchased.

- Purchased, but not added to a ticket.

You can do this using Part Orders (for returns or purchases) or Tickets (to sell the part).

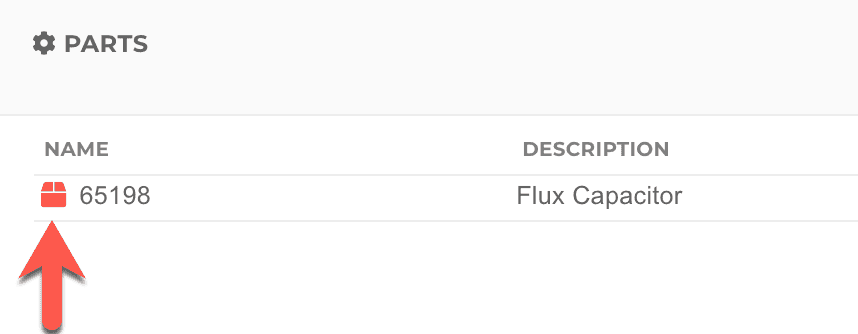

Unpurchased Part

If you see a red box next to a part in ticket, it indicates that the part is neither stocked in inventory nor recorded in a part order.

In these cases, you should add the part to a part order to make sure that there is a record of you purchasing the part.

Stocked Inventory

Stocked Inventory is for all the items you keep in-stock at the dealership. Some examples:

- Fluids

- Oil, coolant, transmission

- Oil filters - common ones at least

- Bulbs

- Hardware

- Bolts

- Nuts

- Gaskets

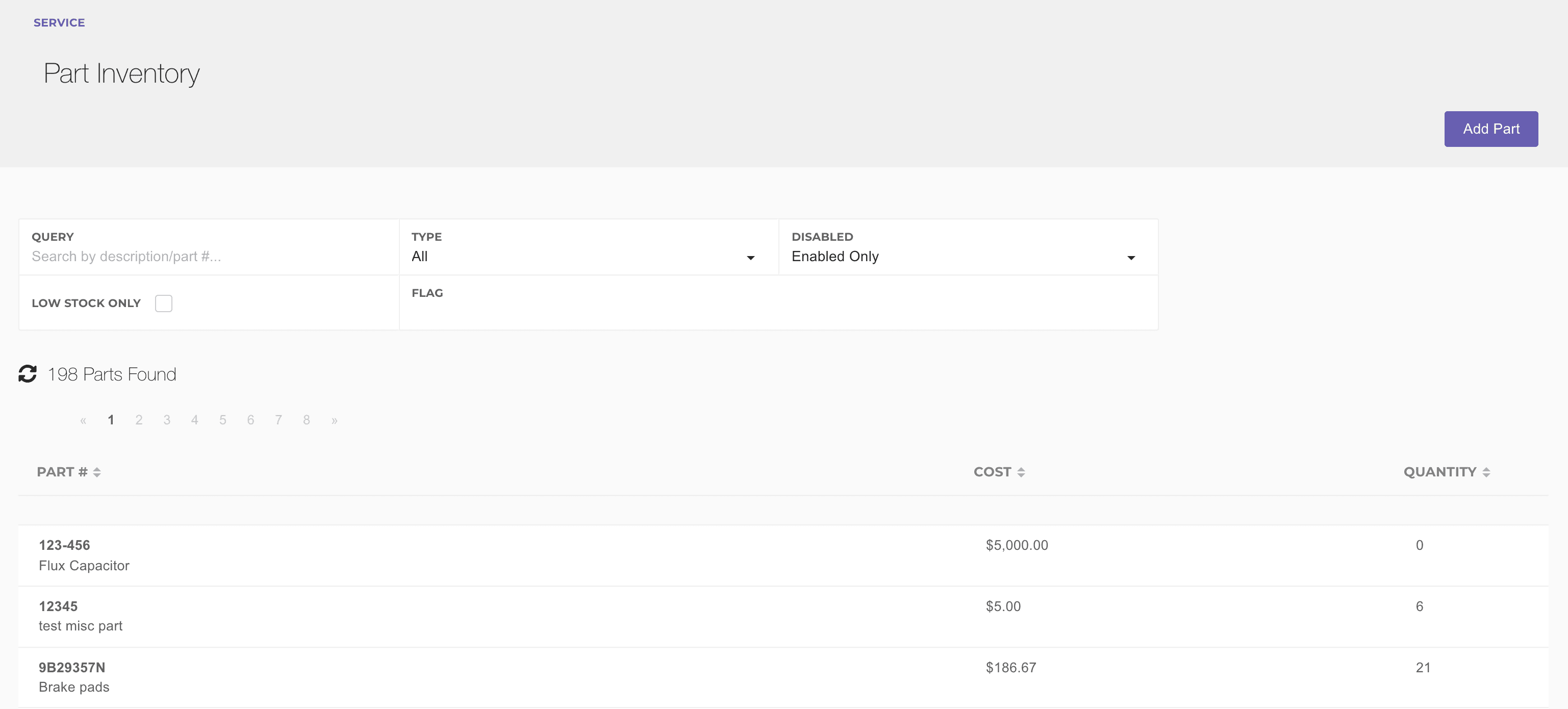

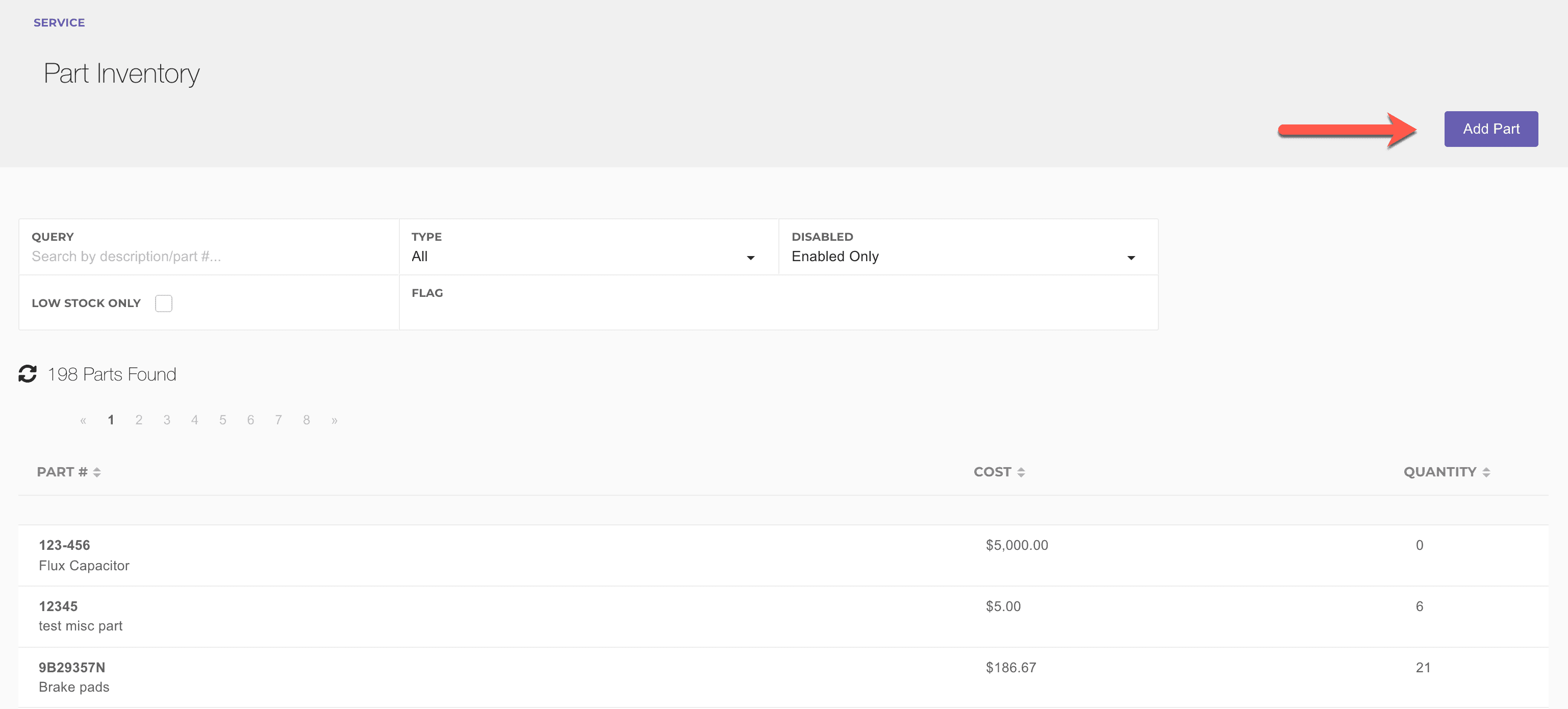

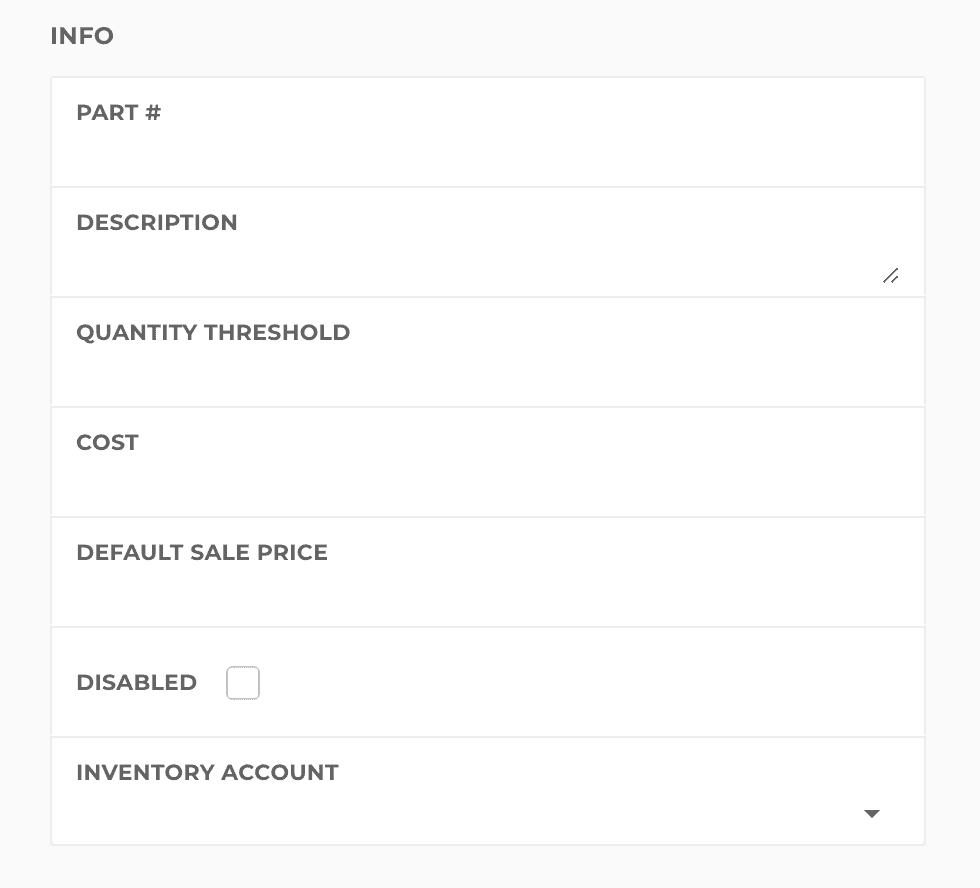

Create New Stocked Inventory

If you haven't stocked a particular part yet, new Stocked Inventory must always be created first in Part Inventory before you can purchase it using a Part Order.

- Part # - The part number.

- Description - A multiline field for the description of the part.

- Quantity Threshold - The minimum quantity you want to keep in inventory. Once you have less than this quantity in inventory, a notice will be shown on this part.

- Cost - The cost of this part.

- Default Sale Price - The default sale price to be used when adding this part to a ticket

- Disabled - For parts that are no longer used or stocked.

- Inventory Account - Override the inventory asset accounting account that this part should be stored in. This cannot be changed after creating the part.

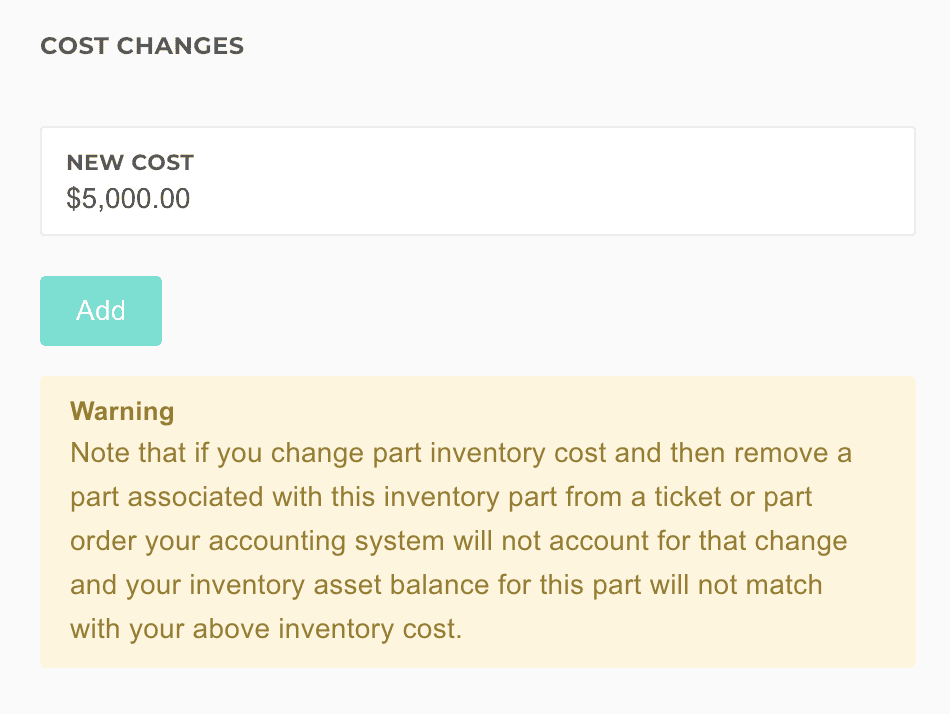

Changing Part Cost

Averaging the Cost

The normal way that costs get changed is when you purchase the part for a different cost on a part order. Let's look at an example of purchasing a part whose current cost is 6.00.

Our new cost is $5.33. The additional part cost was simply averaged over all the parts.

Averaging costs happens automatically when you modify a part on a ticket or part order that has a different cost than the cost in part inventory. It can occur when:

- Adding a stocked part on a ticket or PO.

- Editing a stocked part on a ticket or PO (cost or quantity).

- Deleting a stocked part on a ticket or PO.

Each of these items can affect the average cost and quantity in a Stocked Part and therefore can modify the Stocked Part's averaged cost.

Manually

If you want to change a cost on a Stocked Part, you can do so using the Cost Changes section. Adding a cost change here will simply write off the change amount in accounting as an expense or income, depending on whether you're increasing or decreasing the cost. This cost change will only affect future uses of the part.